In this era of pursuing one-stop service for everything, where do you need to consider whether you want a hose or a joint.

Children do multiple-choice questions, and we choose all adults.

Just like the pursuit of being a person with a head and a face, making an assembly with a head and a head is also a malleable goal.

Yatai —— Strive to meet all your expectations of the assembly!

Main Feature:

• No head blow, no head off, high temperature resistance, abrasion resistance, UV resistance, weather resistance

•Computer program-controlled root root pressure test, strong bearing pressure, not easy to wear, small deformation under working pressure, good pulse performance, various colors and appearances can be customized

Main Application:

• Used in engineering construction, lifting and transportation, automobiles, ships, injection molding machines, compressors

• Used for mining equipment, mine hydraulic supports, oil field mining, metallurgical forging

• Used for transporting petroleum-based (such as mineral oil, soluble oil, hydraulic oil, fuel, lubricating oil) liquids and water-based liquids (such as emulsions) with a certain pressure and temperature in various machine tools and various industrial sectors mechanized and automated hydraulic systems , Oil-water emulsion, water), gas, etc. and liquid transmission and other fields.

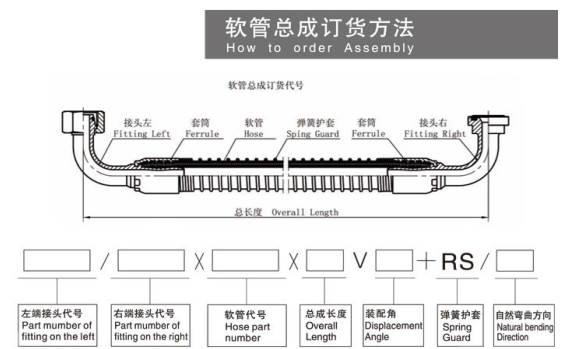

How To Order Assembly:

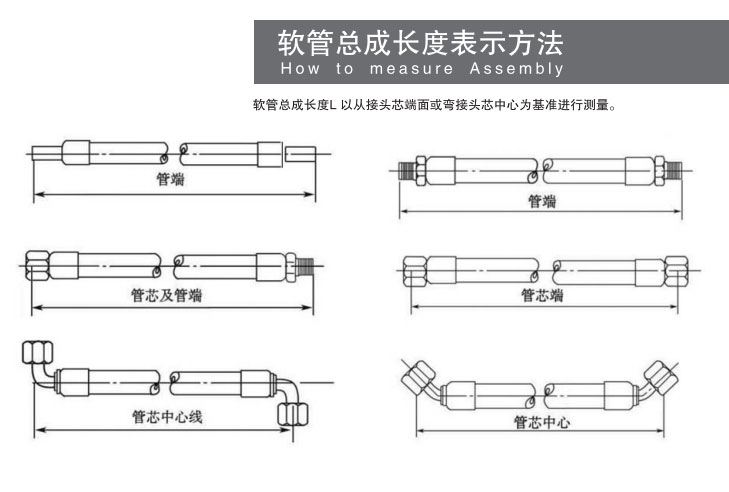

How To Measure Assembly:

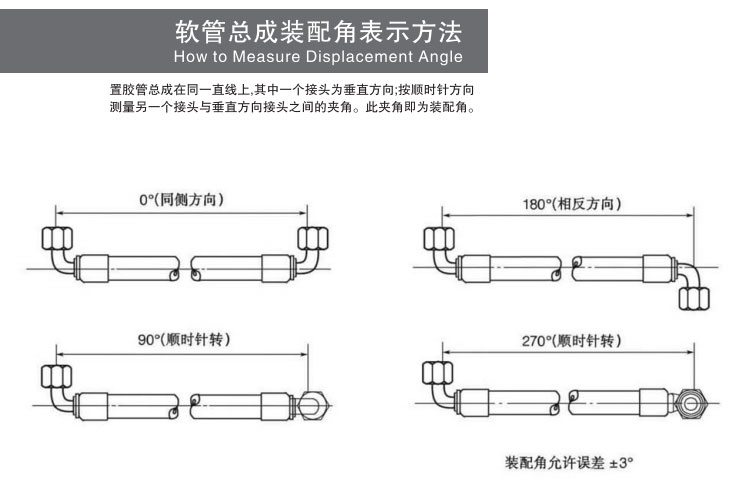

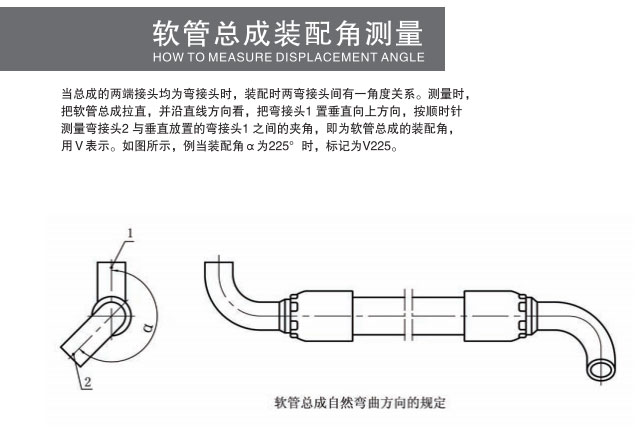

How To Measure Displacement Angle:

How To Measure Displacement Angle:

Installation Method Of Hose Assembly:

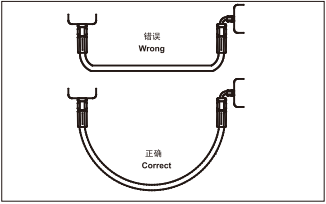

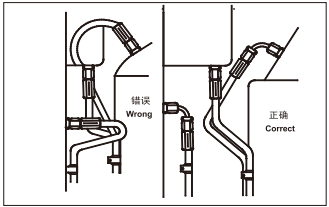

Twisted installation of the hose will greatly reduce the life of the hose, and the twisted installation of the hose will cause early pressure on the joint and loosen the joint

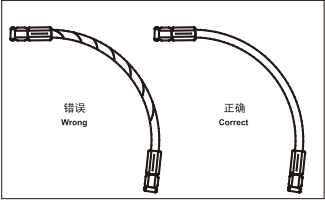

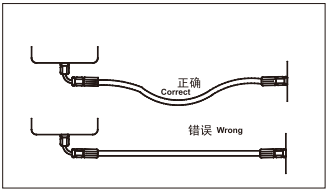

A sufficient bending radius can prevent hose damage and throttling, and a too small bending radius will seriously reduce the life of the hose.

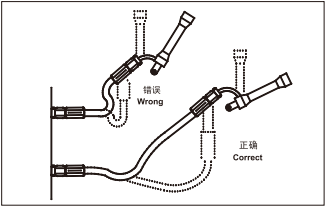

When the hose assembly uses relatively moving parts Please note that the steel hose joints are not deformable Parts, so there must be enough hose free length

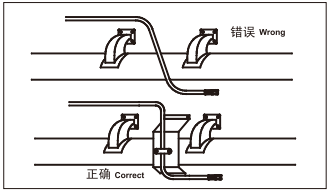

Use elbows or other accessories to reduce the use of glue

The amount of tube to make the arrangement more beautiful, neat and reasonable

Pressure may cause the length of the hose to change, especially it may shrink, up to 2%, so there should be a margin during installation, otherwise it will cause leakage and damage or even the joint will fall off

Pressure may cause the length of the hose to change, especially it may shrink, up to 2%, so there should be a margin during installation, otherwise it will cause leakage and damage or even the joint will fall off

Technical Description:

1. Hose size

The inner diameter of the hose should be appropriate. If the pipe diameter is too small, the flow rate of the medium in the pipeline will be increased, the system will generate heat, reduce the efficiency, and will produce excessive pressure drop, affecting the performance of the entire system.

If the hose is fixed by pipe clamps or the hose passes through spacers such as steel plates, pay attention to the outer diameter of the hose.

2. Work pressure

The dynamic working pressure of the hose in the data refers to the maximum pressure allowed during continuous operation of the hose.

According to the safety factor of hydraulic hoses stipulated by relevant international standards, our recommended working pressure is usually one-fourth of the lowest burst pressure of the hose.

3. Impact pressure and fatigue life

The choice of hose is determined according to the highest pressure value of the hydraulic system design.

Since the pressure value of the hydraulic system is usually dynamic, shock pressure sometimes occurs, and the peak value of the shock pressure will be much higher than the maximum pressure value of the system.

However, the system generally has an overflow valve, so the impact pressure will not seriously affect the fatigue life of the hose.

For hydraulic systems with particularly frequent shock pressures, it is recommended to use hose products that are particularly resistant to pulsation and shock.

4. Temperature range

The user should use the hose within the temperature allowed by the hose quality specification. If the working environment temperature exceeds this range, the life of the hose will be affected, and its pressure-bearing capacity will also be greatly reduced. For systems where the working environment temperature is too high or too low for a long time, it is recommended to use a hose sheath.

5. Chemical compatibility

If a special hydraulic medium is used, the user should ensure that the inner, outer layer, joints and O-ring seals of the selected hose assembly are compatible with the medium.

6. Bending radius

When installing the hose assembly, pay attention to the minimum bending radius of the hose. If the bending radius is too small, the pressure-bearing capacity of the hose will be reduced and its service life will be affected.

7. Friction

The hose always touches or rubs with hard objects when in use. It is recommended to add a spring sheath to the outside of the hose.

There are many factors that affect the use of the hose assembly. Only when the hose and joints are correctly selected according to the working conditions can the reliability and economy of the hose assembly be guaranteed.

For more technical questions, please consult our technical team. Consulting Tel: 15603181870 (WeChat synchronization)