Yatai Hose has been committed to the research and development and innovation of hoses. For the more popular threading pipes at this stage, we have also made a series of research and testing. Welcome to consult.

The threading pipe developed by Yatai is mainly dedicated to various industrial fields such as agricultural machinery, power, subway tunnels, etc., and improves the performance bugs of the original plastic threading pipe, so as to bring greater benefits to customers.

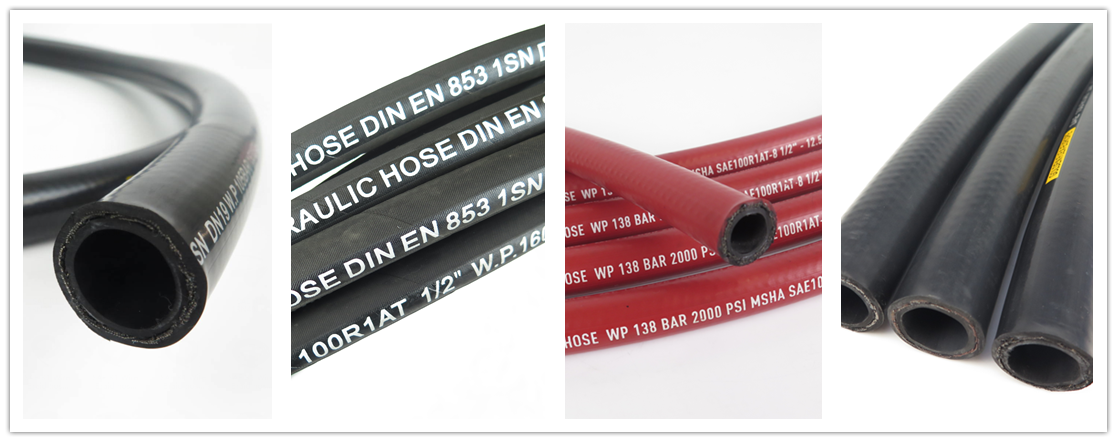

1. Inner diameter of hose: 1/4 ”~ 4”

2. Hose structure:

Inner rubber: EPDM EPDM

Reinforced layer: one layer of steel wire braid or one layer of fiber braid or vacuum tube

Outer layer: EPDM EPDM

3. Color: usually black, other colors can be customized

4. Use environment:

4.1 Plateau, plain and high-sand sand area

4.2 Storage temperature: -40 ℃ ~ 150 ℃

4.3 Working environment: -40 ℃ ~ 150 ℃

5. Performance: It has strong wear resistance, weather resistance, aging resistance, ultraviolet resistance, flame retardant and good bending performance, and has a high adaptability to the external environment

Due to the particularity of the use environment, the requirements for hoses are higher. Threading tube produced by our factory

Meet the following experimental standards in each performance test:

①Insulation resistance test, in line with GB / T 9572-2013 rubber and plastic hose assembly resistance and conductivity measurement standards

② Low temperature deflection test, in line with GB / T5564-2006 rubber and plastic hose low temperature deflection standard

③ High-temperature experiment, in line with the provisions of 11i of GB / T 5095.6-1997 Basic test procedures and measurement methods for electromechanical components used in electronic equipment

④ Ultraviolet condensation test, in line with GB / T16585-1996 vulcanized rubber artificial weathering test method

⑤ Abrasion resistance test, in line with GB / T12721-2007 rubber hose outer coating wear resistance performance measurement standard

⑥Ozone resistance performance, in line with GB / T 24134 rubber and plastic ozone resistance evaluation method under soft static conditions 4

⑦ Burst pressure test, in line with GB / T 7939-2008 hydraulic hose assembly degree method standard

⑧Flame retardant test, not less than DIN5510-2 Railway vehicles Combustion characteristics and combustion prevention materials and components and found S3 grade

⑨The smoke level is not lower than SR2 level in DIN5510-2

⑩ Melt drop level is not lower than ST2 level in DIN5510-2

Please consult our sales and technical staff for more details.

Technical hotline: 15603181870 (WeChat synchronization)

QQ: 1654470252

E-mail: sophie@chnhose.com

Skype: sophie.lei010